Verification vs. Validation:

- M. DuBose

- 5 days ago

- 2 min read

Verification vs. Validation is the Lesson Every Food Safety Professional Should Master

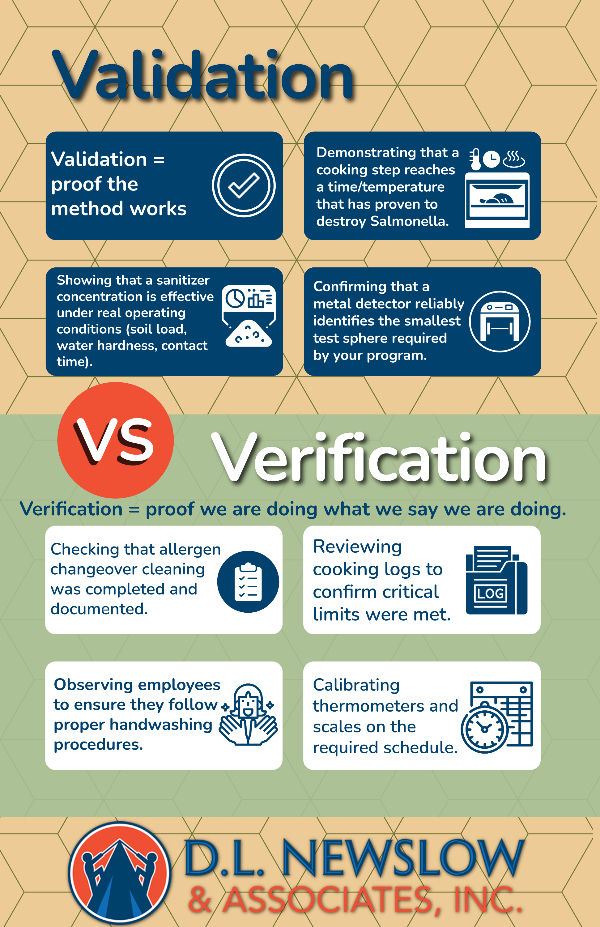

In food safety, few concepts create more confusion during certification than Verification and Validation. They appear together in standards, they sound similar, and yet they serve completely different roles in a food safety system. Understanding the difference isn’t just academic, it directly affects audit performance, employee confidence, and the credibility of your food safety plan.

When employees understand this distinction, they communicate more clearly, respond to auditor questions with confidence, and recognize how their daily tasks support the integrity of the entire food safety system. Validation builds the foundation; verification keeps the structure standing. Together, they form one of the most important and most teachable concepts in any certification program.

What does Validation really mean? Validation answers the questions: Does this control actually work to achieve the intended food safety outcomes? It is the scientific proof behind a process or preventive control.

Common examples include:

Demonstrating that a cooking step reaches a time/temperature that has proven to destroy Salmonella.

Showing that a sanitizer concentration is effective under real operating conditions (soil load, water hardness, contact time).

Confirming that a metal detector reliably identifies the smallest test sphere required by your program.

Validation is typically done before the process is implemented and whenever significant changes occur. It relies on scientific literature, regulatory guidance, challenge studies, or internal testing.

What does Verification really mean? Verification asks: “Are we consistently doing what we said we would do?” It ensures the system is functioning as intended, day after day.

Examples include:

Reviewing cooking logs to confirm critical limits were met.

Observing employees to ensure they follow proper handwashing procedures.

Calibrating thermometers and scales on the required schedule.

Checking that allergen changeover cleaning was completed and documented.

Verification is ongoing. It provides confidence that validated controls are being executed correctly.

A simple way to teach the differences is:

Validation = proof the method works

Verification = proof we are doing what we say we are doing.

The distinction becomes especially important when auditors ask questions like:

“How do you know this process is effective?” (Validation)

“How do you ensure this process is followed every day?” (Verification)

“Show me how you verify this control.” (Verification)

“What scientific basis supports this critical limit?” (Validation)

When employees can answer these confidently, the entire audit feels smoother and more controlled.

Concept | Purpose | Example Question | Example Activity |

Validation | Prove the method works | “What scientific evidence supports this limit?” | Challenge study, literature review |

Verification | Prove we are doing it | “How do you ensure this is done as defined every day?” | Record review, calibration, observation |

Why does this matter for Certification? Certification bodies expect teams to understand these terms because they reflect the backbone of a functioning food safety system.

When employees grasp the difference, they:

Communicate more clearly with auditors

Understand why their daily tasks matter

Recognize how monitoring, recordkeeping, and calibration support the bigger picture

Strengthen food safety culture by connection science to practice

Verification vs Validation: Validation builds the foundation. Verification keeps the structure standing. Together, they form one of the most essential and most teachable concepts in food safety.

Comments